Editor’s note: This article is the second in a series of mini-articles that outline the benefits and the value proposition available by Salamander heaters. This article discusses the benefits of the BoostWell™ heater.

Document also available for download (pdf) here.

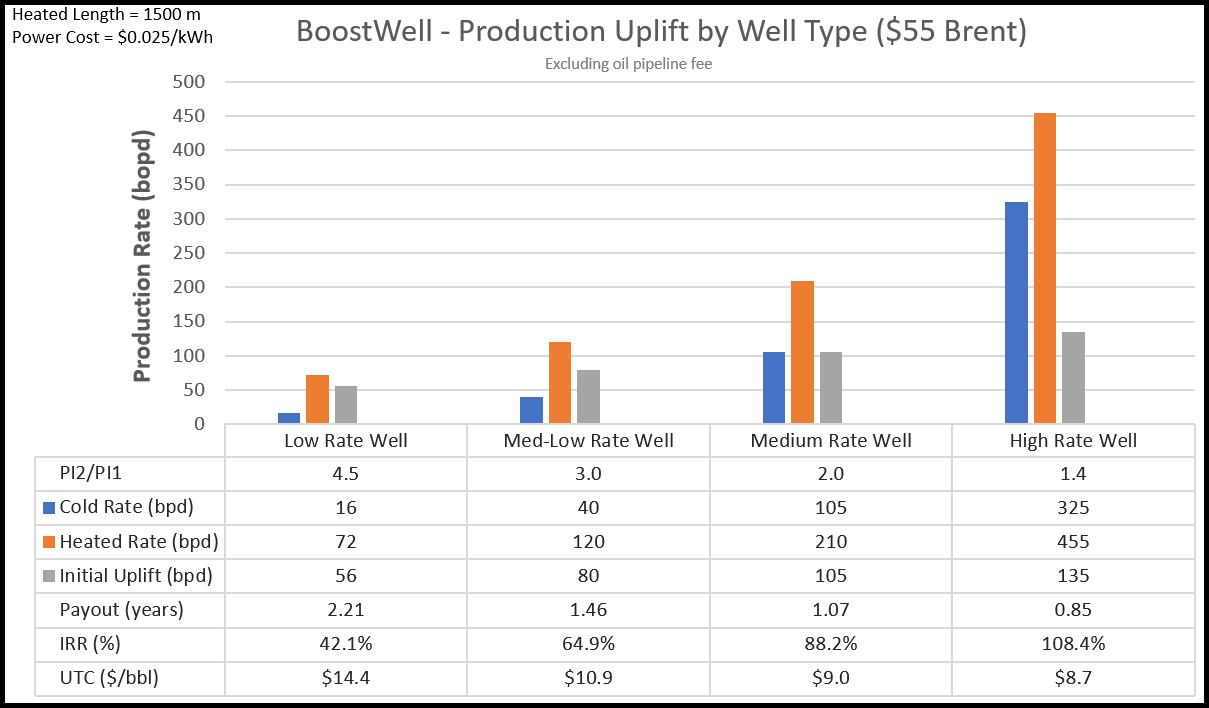

Salamander Solutions, a spin-off from Shell, is bringing advanced heater technology to bear on oil field challenges to improve profitability of difficult hydrocarbons. Salamander heaters can add incremental barrels at $10 – $15/bbl with payouts of 1.0 to 1.5 years. Deepwater applications can result in simplified field layouts significantly lowering field development costs. The goal of the Salamander team is to commercialize the technology bringing benefits to heavy oil and deepwater fields around the globe.

Salamander BoostWell™ Heater

The advanced manufacturing process developed and tested by Shell over 15 years enables Salamander to build heaters in unprecedented lengths and power levels. One application is the deployment in producing wells operating under primary production in heavy-oil reservoirs. Heating increases oil production both accelerating the oil recovery and adding incremental production.

The application of heat to improve the oil production from high viscous “cold” wells has been known for years, but until now has been limited to short vertical sections. The reduction of the oil viscosity in the vicinity of the heated borehole as well as inside the production tubulars results in a larger effective diameter of the borehole and in lower skin. In addition, in the case of long horizontal wells, the reduction in viscosity inside the production liner results in lower pressure at the toe of the wellbore, which allows for potential significant increase in oil production from this poorly tapped section of the reservoir. Additional benefits include the reduction in water coning and an increase in the efficiency and operating life of the downhole pump.

The same economic forces of lower cost per foot of exposed resource that produced benefits for drilling long horizontal wells apply to heating long horizontal wells. Salamander’s is uniquely positioned to manufacture and deploy an unprecedented combination of long length, high power heaters.

Salamander BoostWell™ Heater – Alberta Case Study

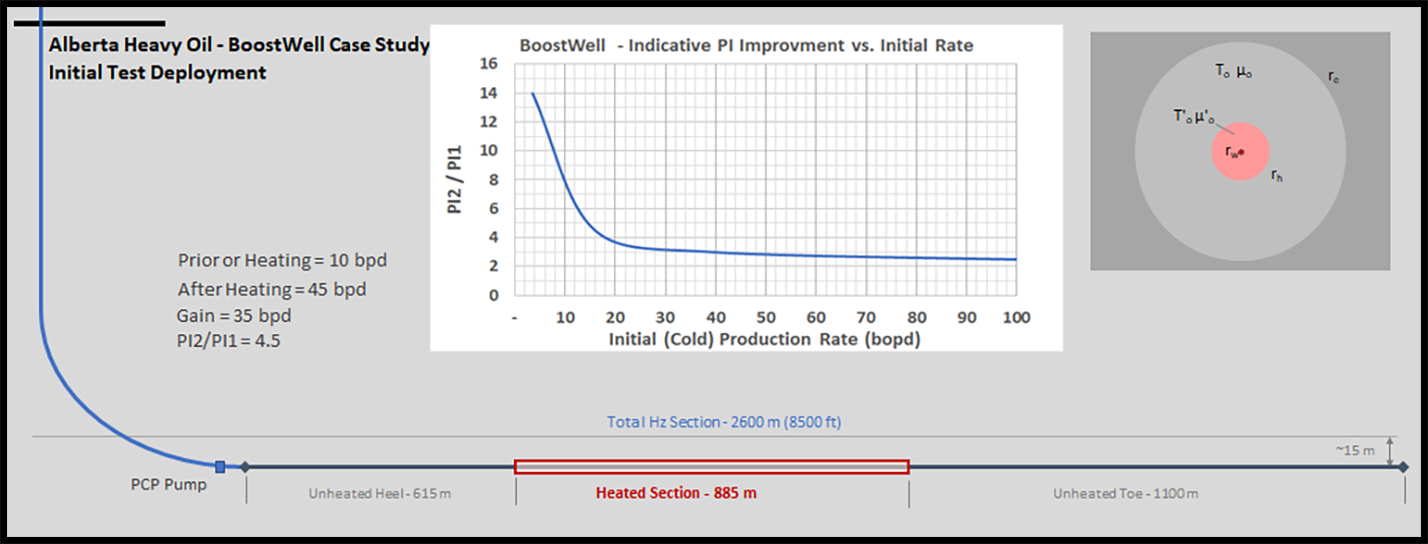

Even though the benefits of a downhole heater are maximized by deploying it earlier in the production life of the well it can be retrofitted into existing wells with declining production. An example of such a deployment, in a cold-producing well in a heavy-oil field in Alberta, Canada is discussed below, starting with a schematic of the stimulated well and a photograph from the deployment of the heater.

A Salamander Solutions downhole electrical heater was installed in December 2016 in a ‘cold producer’ horizontal well in a field owned by Shell Canada. The 885-meter-long heater was placed about 600 meters away from the pump so that it could heat the region of the reservoir that, according to our reservoir models, was not being adequately depleted during cold production. This configuration leaves more than 1000 meters of unheated section between the end of the heater and the toe of the well, which offers room for optimization when the technology is replicated across the field. The heater was energized in April 2017 after the rate of oil production had reached its (pseudo) steady-state level and it has been operating for the last ten months.

The rate of cold production from this well was 10 barrels per day. Upon energization of the heater there was an immediate increase in the rate of oil production, which continued to climb to about 45 barrels/day, i.e. a Productivity Improvement Factor of 4.5x. The increase in oil production was accompanied by an increase in gas production but a decrease in water production.

The success of this ongoing project will be formally evaluated at the end of the 1st Quarter 2018, after a twelve-month heating period. However, results to date provide confidence to generate indicative economics for BoostWell™ general cases; selected economics metrics are shown in the following graph:

Next Month: Salamander LinkWell™ Application to improve the productivity of SAGD wells will be featured.