Onshore

Viscosity Improvement

Cold flow oil wells produce at relatively low rates due to their high viscosity. A downhole pump must pull hard to enable flow, which often draws in high volumes of water. A boost in temperature decreases oil viscosity and will increase oil production by up to 5 times with minimal increase in absolute levels of water production. A custom-designed Salamander heater deployed in long horizontal cold-flow wells will propagate heat into the formation, increase oil production and reduce the water cut (i.e. water production as a percentage of total fluid production) for the life of the well.

Benefits

- Higher oil production rates per well

- Fewer well interventions. Lower viscosity and stable flow rates increase life expectancy of pump systems

- Smaller footprint. Fewer wells, no need for diluents and smaller water handling facilities

- Can be deployed in new or existing wells – the sooner the better

- Easy to operate

- Quick payback

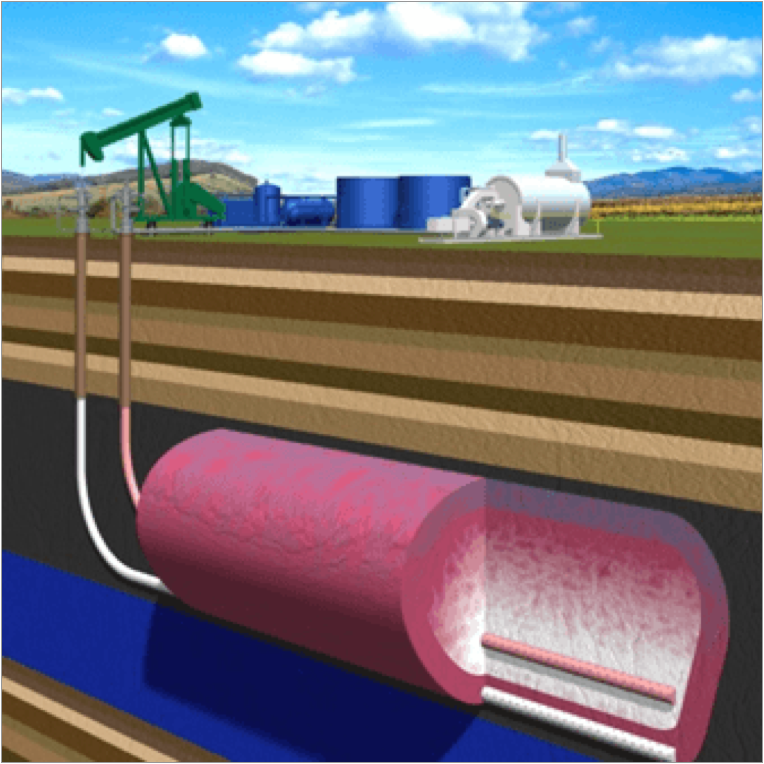

Flow Assurance

Depositions of wax, sulfur, and hydrates restrict flow and put strain on artificial lift systems, which result in lower production rates. Salamander’s technology enables precise control of temperature and heat output to maintain fluid temperatures at pre-determined levels – high enough to prevent the precipitation of solids, but low enough to stay within the optimal operating temperatures of the equipment. The result is a smoother, more reliable flow and longer equipment life.

Benefits

- Eliminates solids precipitation

- Reduced downtime and well interventions. Improves flow and prevents solids from compromising artificial lift

- Eliminates need for downhole chemicals

- Easy implementation in new or existing wells

- Easy to operate

- Quick payback

Enhancement or Replacement of Steam Operations

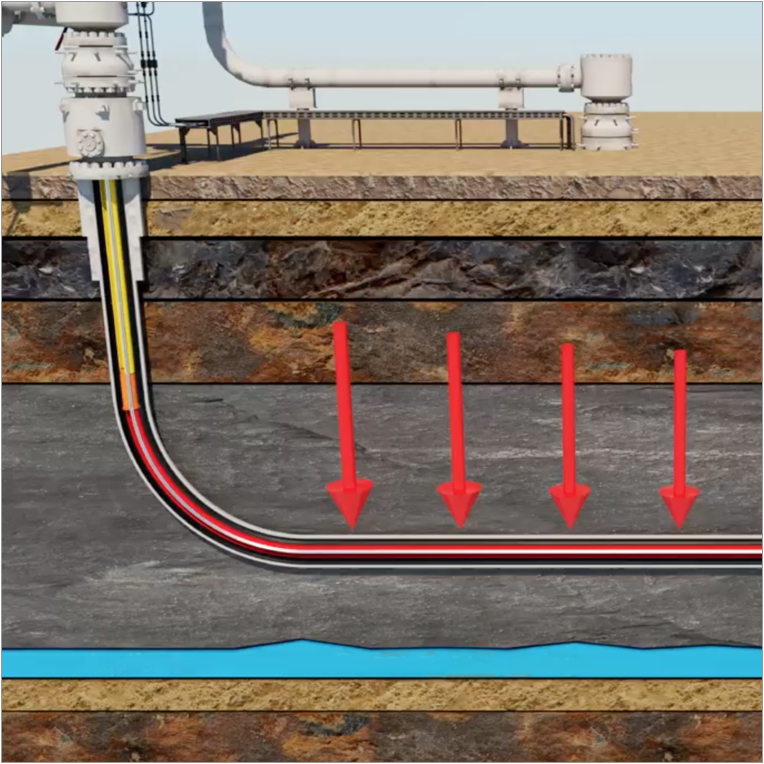

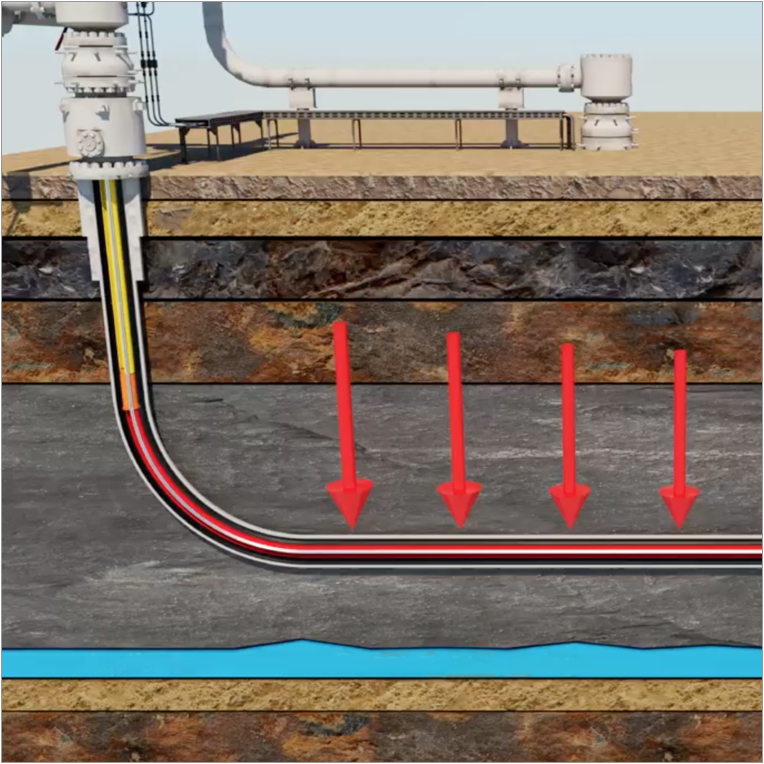

Salamander heater cables can be used to complement steam operations in SAGD (Steam Assisted Gravity Drain) and CSS (Cyclic Steam Stimulation) production.

In SAGD the heaters can be used in injection and production wells, prior to the start of steam injection, in order to improve the efficiency and conformance of the actual steam injection process and to achieve a more uniform penetration of the steam along the wellbore. The heaters can also be used in injection wells during steam injection to improve the steam quality in the wellbore.

In CSS operations the heaters can be used prior to and/or during the injection phase of the CSS to improve the efficiency, quality, and conformance of the steam; and during the production phase to maintain the temperature of the near-wellbore and extend the duration of the production phase of the cycle. This results in more oil production per cycle and fewer cycles over time.

The technology can be integrated into existing systems or installed ahead of surface steam facilities to loosen-up the reservoir and accelerate first oil. This solution also significantly reduces the amount of water needed in steam operations as well as the emissions related to steam generation.

Benefits

- Accelerates SAGD well connection resulting in faster first oil

- Better conformance and sweep profile in wells with long-laterals (>750 meters)

- More oil production per cycle in CSS

- Technology can be deployed in wells with laterals that extend beyond the limit of steam

- Optimizes, reduces or eliminates water usage

- Lower emissions per barrel of oil produced

- The heaters can be deployed in shallow or deep wells that are not suitable for steam

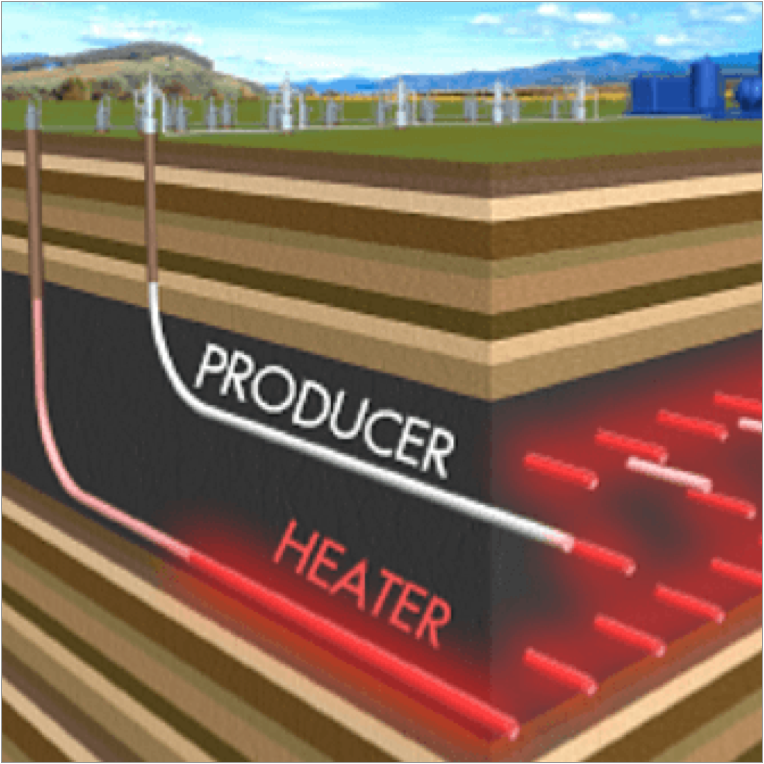

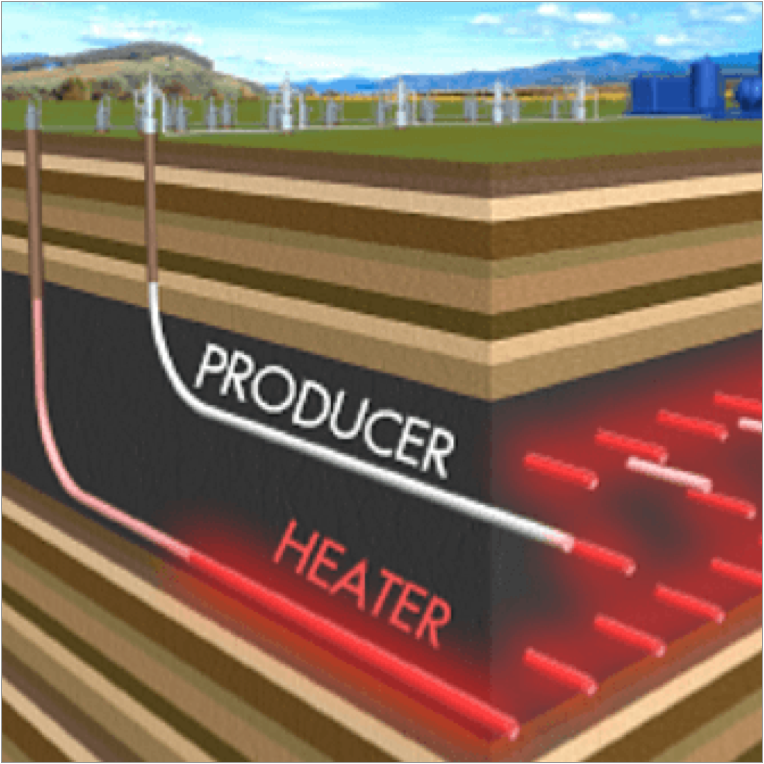

Enables In-situ Conversion (ICP) In-situ Upgrading Process (IUP), and Hybrid Drive

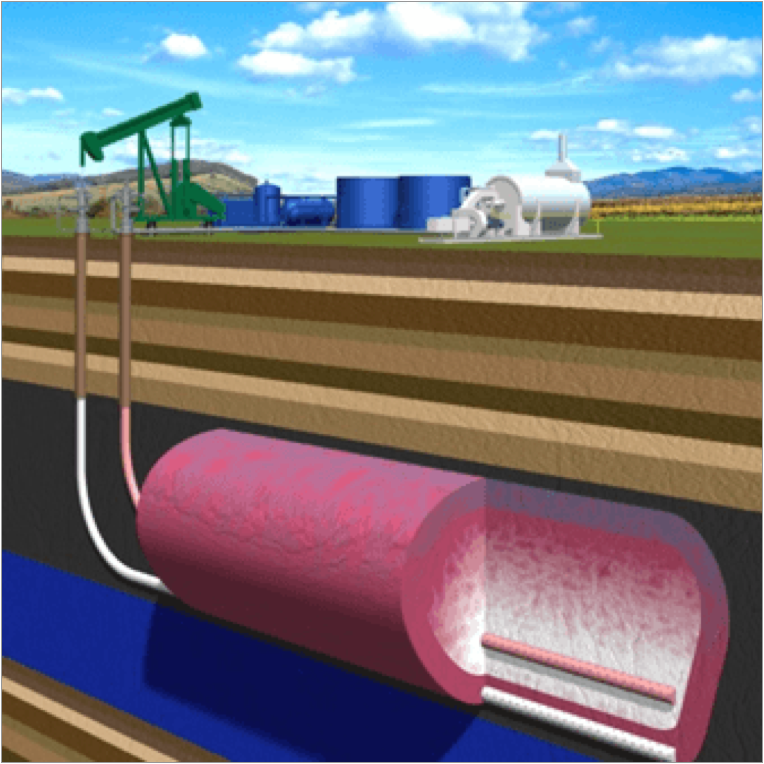

Through closely spaced heaters, Salamander technology can be used to increase temperatures throughout the entire reservoir to extract hydrocarbons from immature kerogen-rich shales or heavy oil and bitumen, and generate reservoir drive.

Benefits

- Increases recovery factors to 50% for ICP and 75% for IUP with energy ratios nearing 10

- Eliminates the need to purchase diluents. The process can produce oil with API gravity between 16°–50°, depending on what is most economically favorable

In-situ Conversion Process (ICP)

Surface retorting methods for extracting value from kerogen-rich shales are neither efficient nor cost effective for depths greater than 100 m. But with Salamander’s heater-enabled ICP, these vastly undervalued hydrocarbon resources can be more efficiently converted in-situ through the precise application of heat to recover 50% (by weight) of the organic content of the rock.

In-situ Upgrading Process (IUP)

In-Situ Upgrading Process (IUP) uses Salamander heaters to initiate thermal cracking of heavy oil or bitumen. Due to more uniform heat propagation relative to steam, recovery efficiencies reach as high as 75% with subsurface energy ratios nearing 10 in some cases.

In addition, IUP allows for the control and variation of oil characteristics to APIs between 16° and 50°, which can reduce or eliminate the need for diluents. Downstream costs are further reduced because the heater-enabled-process leaves most of the waste products such as coke, metals, and sulfur in the ground.

Special Applications

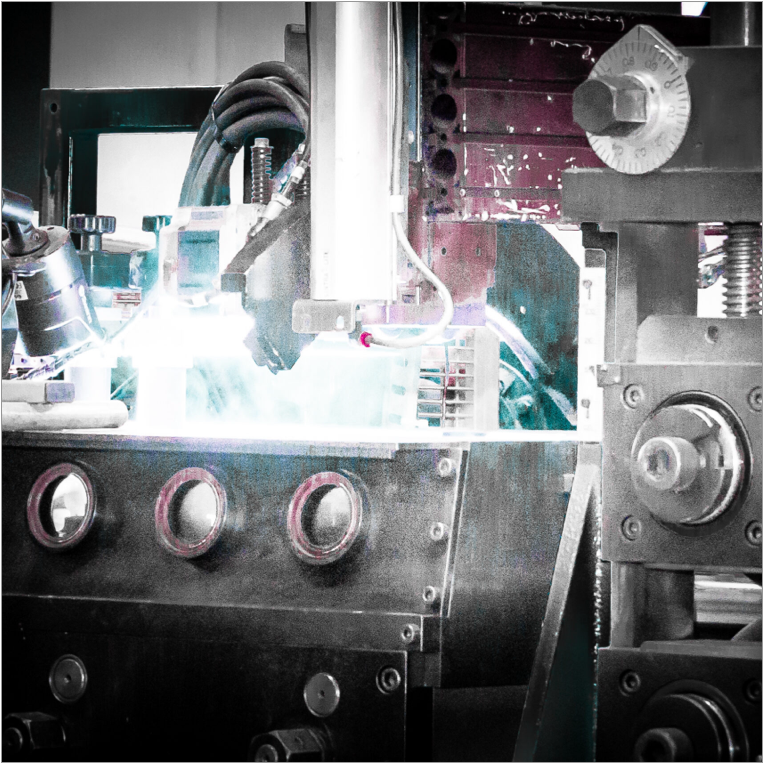

With operating temperature limits of up to 1200F/650C, no external splices and ability to withstand extreme pressures and pull forces, Salamander heater cables can also be used to deliver unparalleled high power (in the thousands of W/meter) to short and targeted cable sections for a variety of downhole and surface special applications. Some of these include:

- Ice or liquid drop-out in high-rate gas producers or CO2 injectors from Joule-Thomson cooling

- Well abandonment (SPE Paper 191607)

- Downhole steam generation or steam quality improvement

- High-temperature transfer lines

- Power to heat

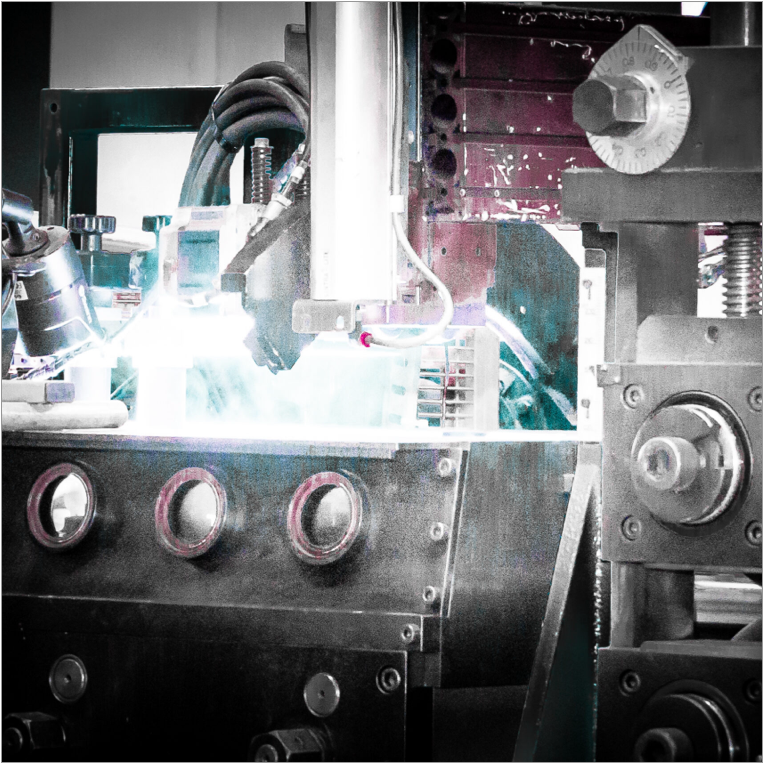

The Salamander team of professionals has expertise in reservoir, well, process, and pipeline heating. Salamander’s self-owned manufacturing facility and extensive deployment history ensure the high quality of its products and the reliability of its processes.