Offshore

Our high-performance heater cables effectively address the most persistent issues limiting oil production in the deepwater environment. Applications improve performance on:

New flowlines

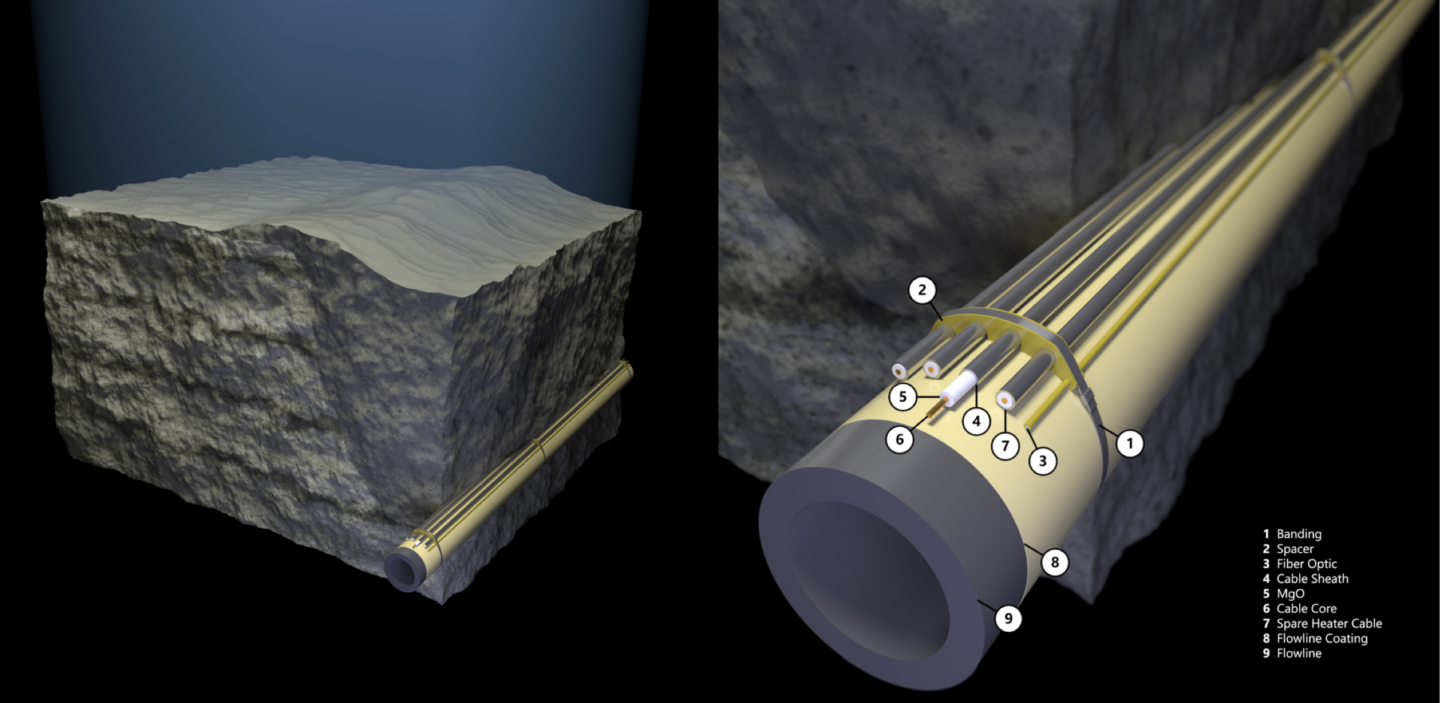

Our technology prevents hydrates and wax plugging, enables longer tiebacks (up to 80 km), and can be extended as needed after initial installation. This allows for more flexible and less risky field planning and for companies to capture stranded volumes (i.e. farther out from existing hosts) without having to invest in new host facilities.

Existing flowlines

Our technology can be retrofitted permanently onto lines to remediate hydrates and wax plugs and prevent them from re-occurring. This results in delayed abandonment rates and wells that will keep producing significant volumes for longer and with fewer interruptions. Reducing chemical costs, operating costs, and deferring well abandonment costs will all result in increased well profitability.

Plugged flowlines

Our technology can also be deployed temporarily on existing lines to remove plugs without physical intervention in the flowlines’ pressure integrity system. This make plug removal safe, cost-effective, and environmentally friendly.

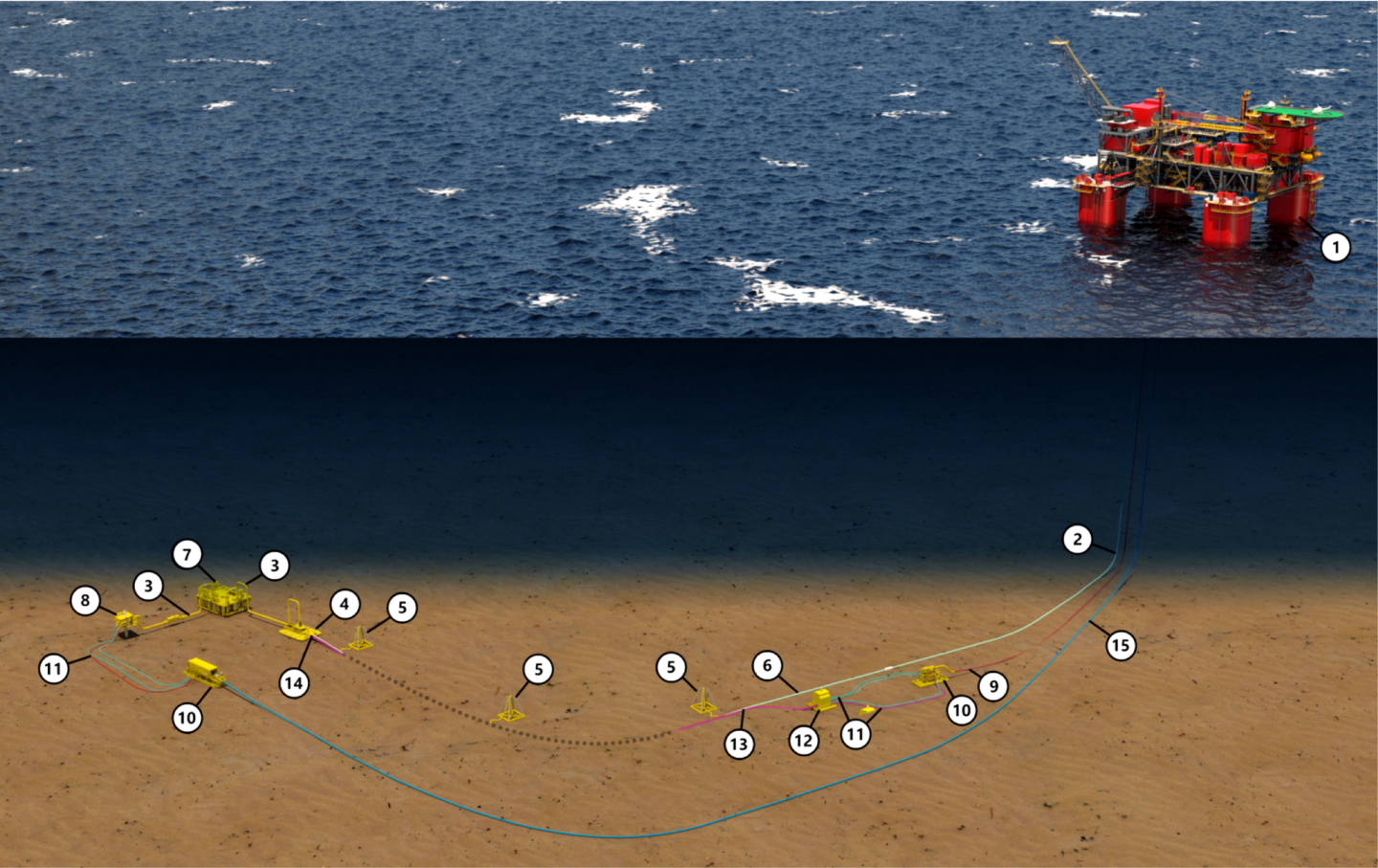

- Platform

- Riser

- Jumper

- PLET

- Anode Sled

- Flowline

- Manifold

- Xmas Tree

- Power/Fiber Umbilical

- Umbilical Termination Assembly (UTA)

- Flying Leads

- Wet Connect

- Heater and Instrument Attachment Point

- Termination

- Controls Umbilical